In two core fields—printing plate-making and photovoltaic (PV) screen printing—the CTS plate making laser Module is gradually replacing the traditional film-based plate-making process. It has become the industry mainstream due to its advantages of high precision, high efficiency, and low cost.

Core Working Principle of the CTS Plate Making Laser Module

The core principle of the CTS plate making laser Module lies in the closed-loop collaboration of “digital signal → laser control → photosensitive imaging.” Through the coordination of three core components, high-precision plate-making is achieved. The complete workflow consists of four interlocking stages, ensuring imaging quality at every step:

1. Digital File Processing: Precisely Interpreting Plate-Making Requirements

Before plate-making, import design files (e.g., printing patterns, PV cell silver paste circuits) into the system for RIP processing. RIP converts complex graphics/text and circuit info into laser-module-recognizable dot matrix data. It also sets key parameters like resolution, acting as a precise “work map” for the laser. This ensures every laser-irradiated point fully meets design requirements.

2. Laser Emission & Optical Control: Precisely Regulating Beam Shape

As the core working stage of the plate making laser module, it achieves precise light control mainly through the combination of “laser light source + digital micromirror device + high-precision optical lens.” Currently, mainstream modules adopt 405nm wavelength violet laser diodes with optional power ratings (20W, 25W, 30W, etc.), which can quickly cure SBQ-type photosensitive materials and deliver sharper pattern edges.

3. Photosensitive Imaging: Accurate “Reproduction” of Screen Patterns

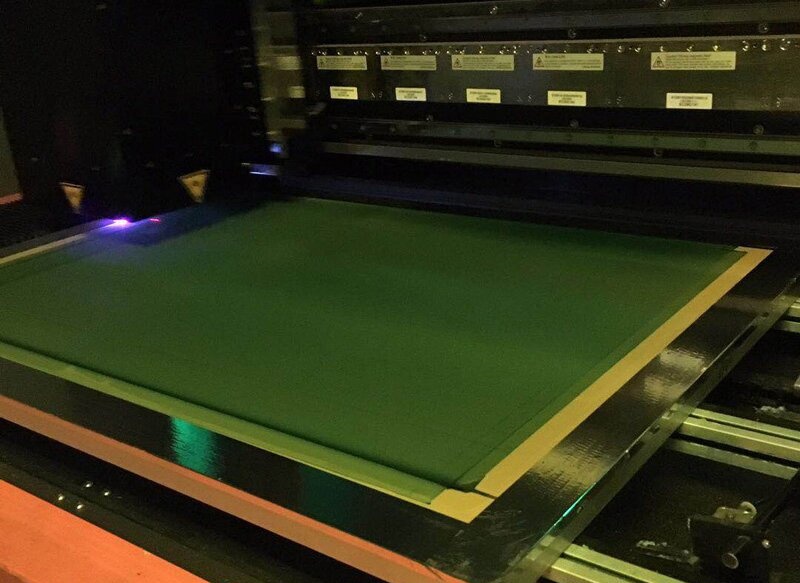

After the screen plate (pre-coated with photosensitive emulsion) receives laser irradiation, the emulsion undergoes a photochemical curing reaction:

- Laser-irradiated areas: The emulsion cures and adheres tightly to the screen plate, blocking the mesh holes.

- Non-irradiated areas: The emulsion remains uncured.

The entire exposure process eliminates the need for traditional film as an intermediate medium, avoiding precision errors caused by film wear or expansion/contraction. It also skips the vacuum lamination step, further reducing the risk of screen plate deformation.

4. Post-Processing Curing: Locking Screen Plate Precision

After exposure, the screen plate undergoes post-processing procedures including developing, rinsing, and drying/curing:

- Uncured emulsion is rinsed away, exposing transparent mesh holes.

- Cured emulsion forms stable “ink-blocking walls.”

The final screen plate features pattern precision identical to the laser-projected dot matrix, with sharp line edges and high dot fidelity. It can be directly used in printing or PV screen printing production.

Summary

Compared with the traditional film-based plate-making process, the principle innovation of the CTS plate making laser Module brings significant advantages:

- Cost Reduction: Eliminates expenses for film production, storage, and development, saving large enterprises hundreds of thousands of yuan annually in consumables and labor costs.

- Efficiency Improvement: Compresses the multi-step traditional plate-making process into a single workflow of “digital file → laser exposure → post-processing,” drastically reducing preparation time.

- Stable Precision: Avoids errors from intermediate links such as film use and vacuum lamination.

Add comment