Light-emitting diodes (LED) and laser diodes(LD)both generate light via electron-hole recombination. They both have a PIN diode at their heart. Even their names sound similar.

So, how are they different?

We’ll start with how we use each, then explore the design differences that turn LEDs into laser diodes.

Common applications

LED: “Lighting for Every Day”

LEDs are a cost-effective and energy-efficient everyday lighting solution. They’re rugged, durable, and generate minimal heat. They come in all colors and shades of white.

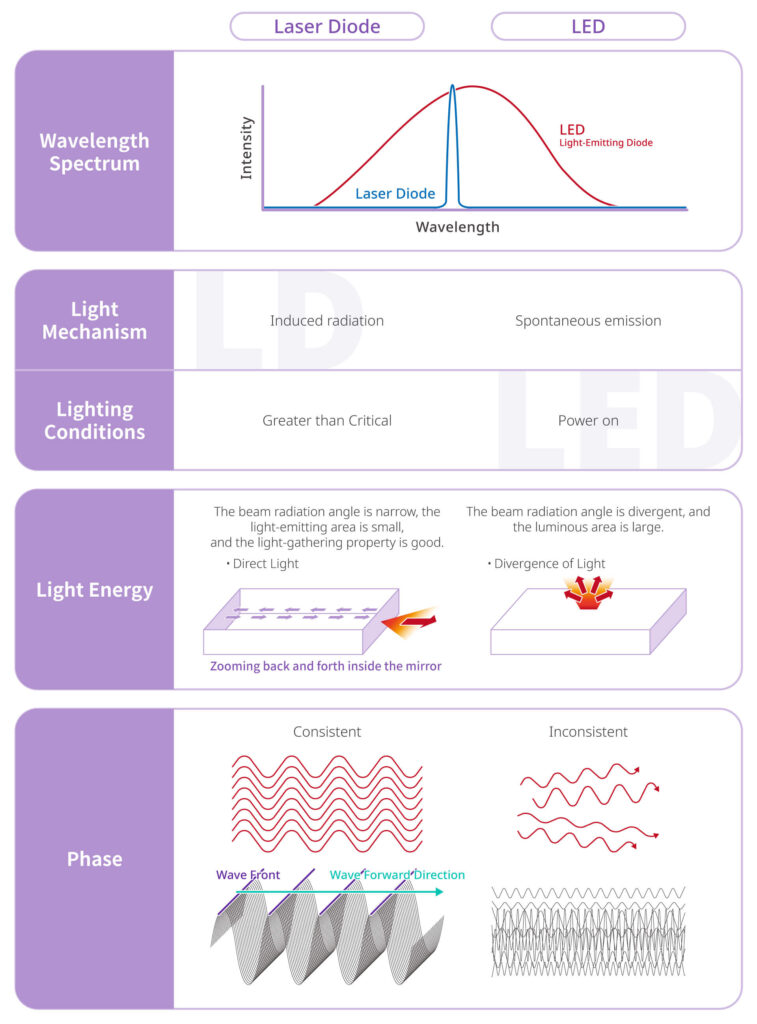

LEDs emit “normal” light (incoherent and multidirectional), just like a fluorescent tube or an incandescent light.

We use LEDs everywhere: street lamps, kitchen lighting, commercial lighting, and electronic devices like Bluetooth headphones and smartphone flashlights.

Laser Diodes: For Science, Industry, Medical and Telecom

Laser diodes share the advantages of LEDs, but emit laser light (coherent and unidirectional).

We use them in laser pointers and specialized scientific & industrial applications (optical pumping of other lasers, spectroscopy, surface hardening, welding).

Telecommunications and optical data storage industries consume laser diodes the most, partly because the diodes have an extremely fast response time—they switch on and off rapidly.

Design differences between LEDs and laser diodes

Both LEDs and laser diodes are PIN diodes. This special type of diode sandwiches an active zone – the Intrinsic (I) region) – between a Negative (N) and Positive (P) region.

Electrons (negative) and electron holes (no electron = positive) recombine in the intrinsic region to generate all light.

Smaller Intrinsic Region –> Population Inversion

In LEDs, the intrinsic region is larger than in laser diodes. This means the photon-producing recombinations happen on a wider surface, which facilitates heat dissipation and can improve durability.

However, for laser light to be produced, you need to obtain population inversion, which can only happen if the density of upper-state carriers is high. To help increase density, the intrinsic regions in laser diodes are made smaller to concentrate the current.

Mirror-like surfaces –> Optical Cavity

In LEDs, any photons created escape immediately. There is no point in keeping them around. In the case of laser diodes, it is very useful to keep photons around, because they become the seed of an eventual laser beam.

By making the edges of the intrinsic region smooth and mirror-like, photons get constantly reinjected into the active region. And because this region is full of excited atoms (thanks to population inversion), stimulated emission can happen, effectively duplicating the reinjected photons. As they get reinjected and reduplicated again and again and again, these photons become a powerful laser beam.

Of course, the laser needs to escape at some point, which is why one edge of the optical cavity (the output) is designed to be only partially reflective.

Summary:The difference between LD and LED

Laser diodes work using a PIN diode, just like an LED. They combine all the advantages of LEDs (budget-friendly, small footprint, low power consumption, rugged and long-lived) but produce laser light.

They do this thanks to a smaller active (I) region and a mirror-like finish, which lets them trap the photons they generate for long enough to amplify them into a laser.

BU-LASER offers semiconductor laser diodes with TO can package from 375nm to 980nm, and we also offer professional OEM& ODM service of the laser diode modules for different applications. If you are interested in the laser diodes and laser diode modules, please contact our sales person at song@bu-laser.com.

Add comment