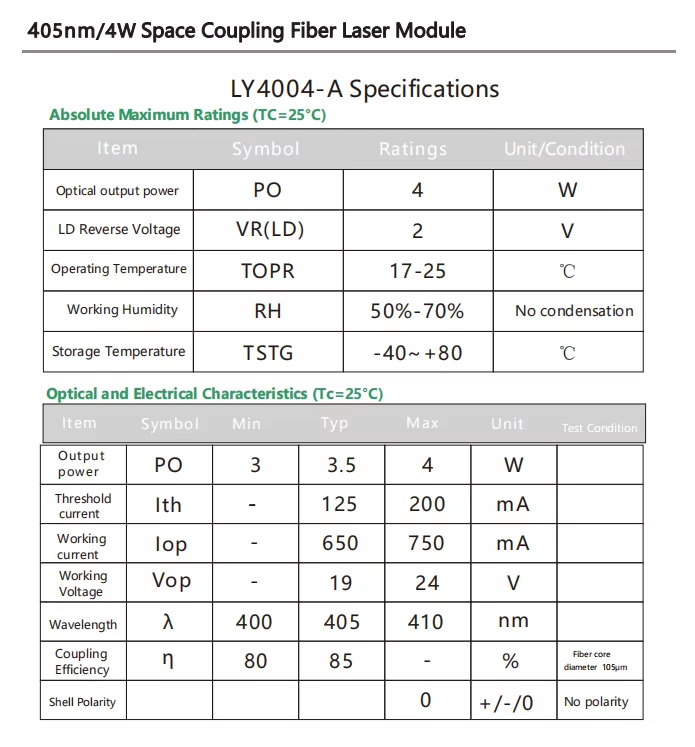

UV 405nm 4W Space Coupling Fiber Laser Module for Laser Direct Imaging

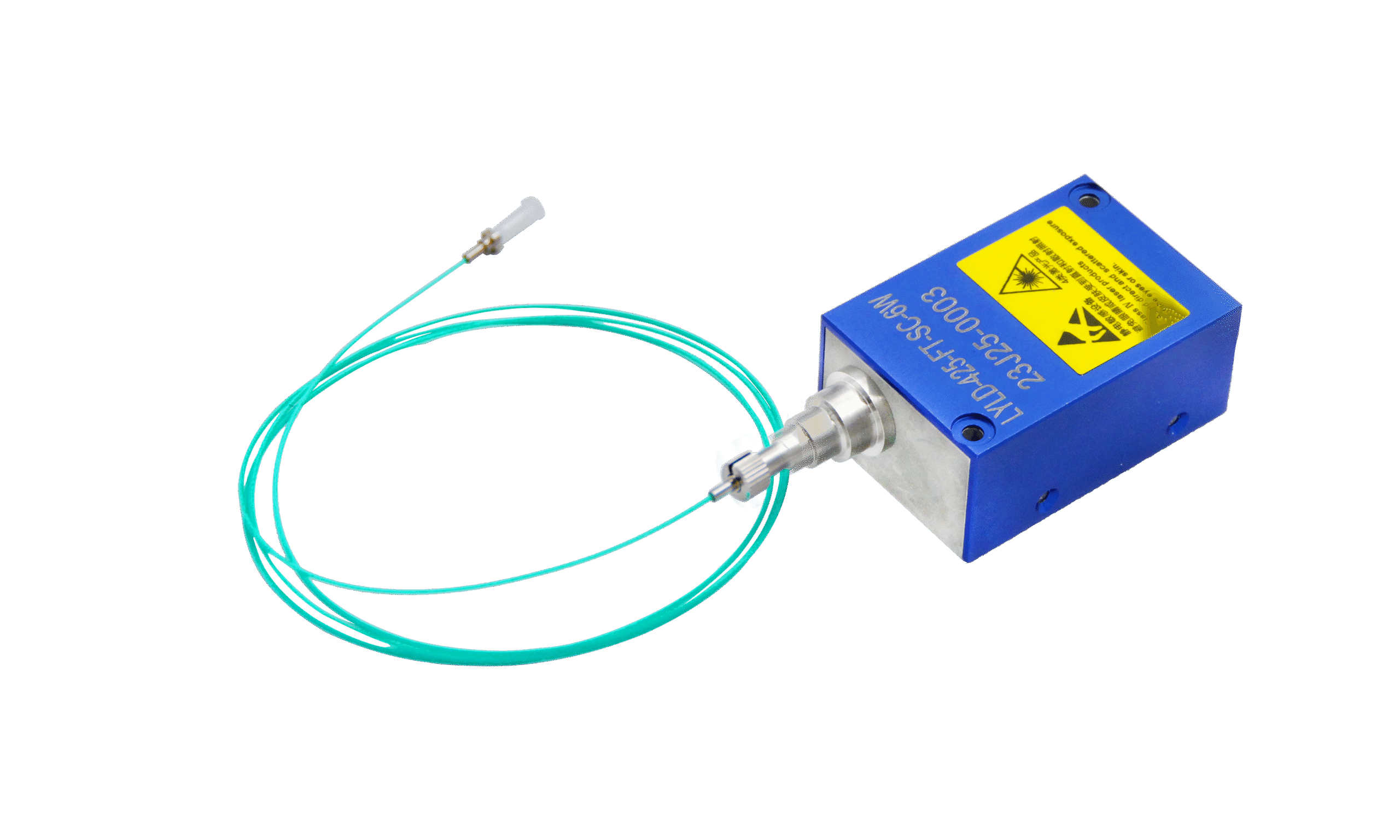

The UV 405nm 4W Space-Coupled Fiber Laser Module, a high-performance industrial-grade light source tailored for laser direct imaging (LDI) systems. Integrating 405nm UV lasers’ photoresist absorption optimization, 4W high-power output, space-coupled beam shaping technology, and precision fiber transmission, it delivers uniform, high-energy laser beams for high-resolution patterning, ideal for PCB fine circuit manufacturing, semiconductor packaging, and flexible electronics imaging.

Core Advantages

405nm UV Wavelength for LDI Photoresist Compatibility

405nm wavelength aligns precisely with the absorption peak of industrial LDI photoresists, enabling efficient photopolymerization with minimal thermal damage to substrates; supports ultra-fine linewidth patterning for high-density PCB and FPC production, outperforming longer-wavelength lasers in imaging resolution.

4W High Power for High-Throughput LDI Processing

Delivers stable CW mode output with lower power fluctuation, providing sufficient energy density for rapid photoresist exposure; reduces LDI processing time by 50% compared to 1-2W modules, meeting the mass production demands of electronic manufacturing lines.

Space-Coupled Beam Shaping for Uniform Imaging

Adopts advanced space-coupled optical design to generate a flat-top beam profile with ≥90% uniformity; eliminates beam hotspots that cause photoresist overexposure, ensuring consistent patterning quality across large-area substrates for PCB panel imaging.

Fiber Transmission & Industrial-Grade Stability

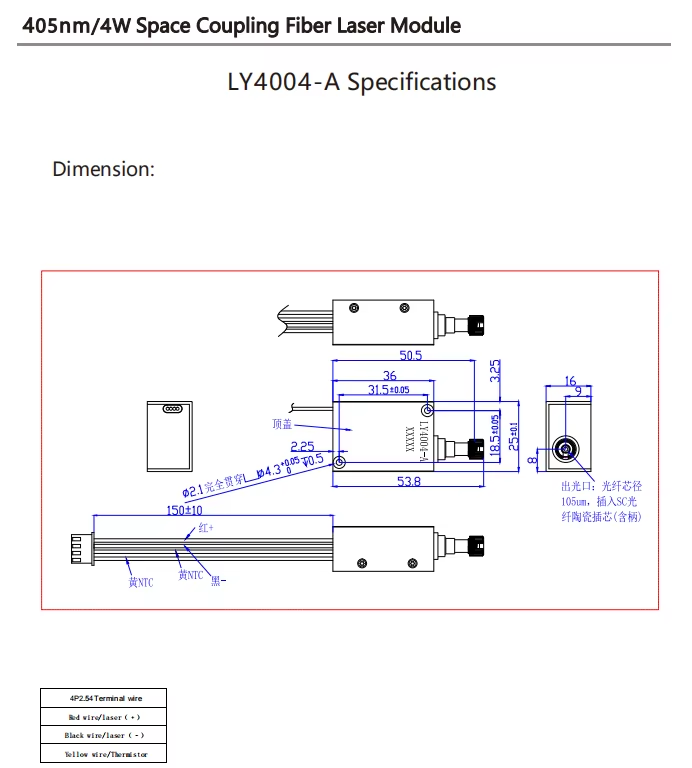

It can be equipped with high-purity UV-grade silica fiber (core diameter 105um/150μm, NA=0.22, coupling efficiency ≥85%); enables flexible beam delivery to LDI scanning systems, avoiding mechanical alignment errors.

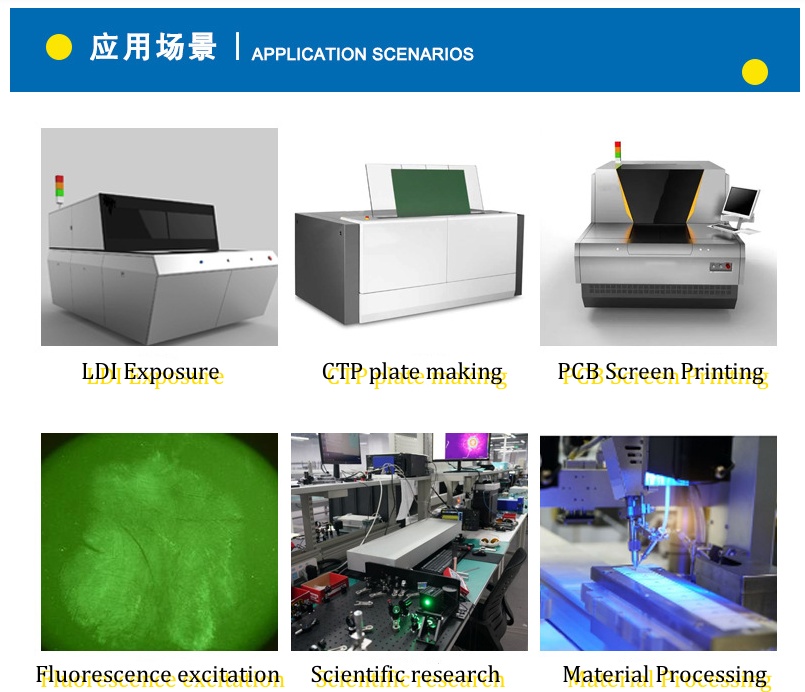

Key Applications

Perfect for laser direct imaging (LDI) in PCB fine circuit patterning, semiconductor packaging lithography, flexible printed circuit (FPC) imaging, and advanced packaging (fan-out wafer level packaging) processes; also applicable to high-precision photomask making and microfluidic chip fabrication.

Reviews

There are no reviews yet.